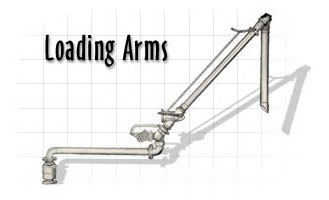

Anyone who has carried a hose onto a slippery tank truck or tank car, or wrestled with an inflexible hose during cold weather or experienced the aftermath of a burst hose, can appreciate the benefits of a counter- balanced flexible piping system (Loading Arm).

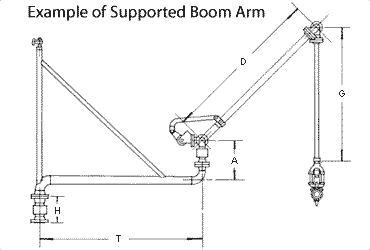

In its natural state, a piping system is not flexible; to make it flexible, swivel joints are put between lengths of straight pipe creating flexibility in the system. The flexibility of the loading arm increases as the number of planes of rotation (swivel joints) are added to the system. To allow for supported vertical movement, a torsion spring or counter weight is utilized. To give or add additional flexibility in reach to these loading arms, both supported booms and unsupported booms can be added to the basic styles.

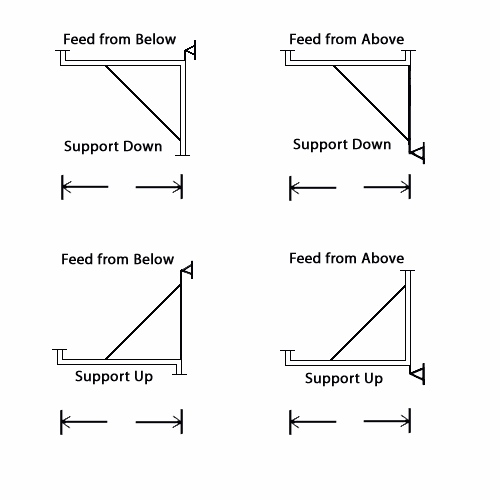

Through a combination of swivel joints and lengths of pipe, you can create a loading arm for your unique applications. The following drawings will assist you in designing your own Loading Arm.

Swivel Joint style 20-F is used on inboard end of booms to give 360 degrees of movement potential.

The maximum reach on an unsupported boom is six feet. Both arms and booms are load sensitive, which can limit choices and dimensions.

To get information or receive a quote fill out our Inquiry Form or email us at sales@cse-ipg.com.

Industrial Products Available: |

| Butterfly Valve | Composite Hose | Dry-Disconnect (Dry-Break) Couplers | Instrumentation Isolation Rings/Iso-Spool® | Lined Ball Valve | Loading Arms (Liquid Loaders) | Quick-Couplers/Camlocks | Safety Breakaway Coupling | Sight Flow Indicators/Sight Windows | Swivel Joints (Swing Joints) | Valved Couplings |

Liquid Fertilizer Products Available: |

| Ball Valves | Dry Connect | IBC/Tank | Line Strainers | Manifold Systems | Pumps |

Oil Marketing Products Available: |

| Bottom Loading Coupler |